The Ultimate Solution for

Windows. Doors. Tilt & Turn. Lift & Slide. Cabinets. CNC Programmers. Manufacturers. Designers.

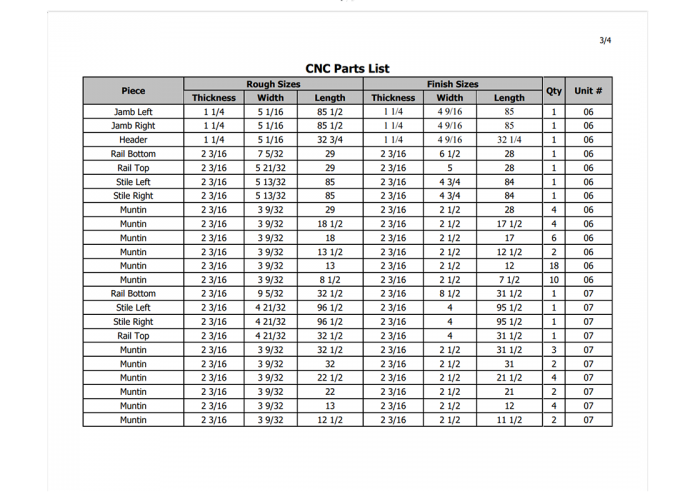

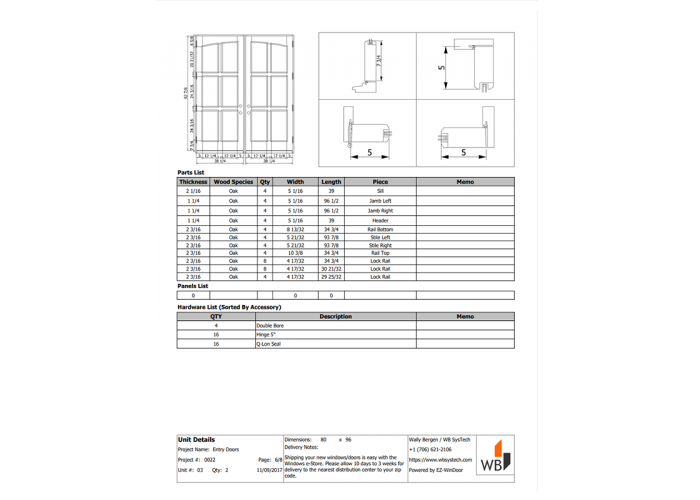

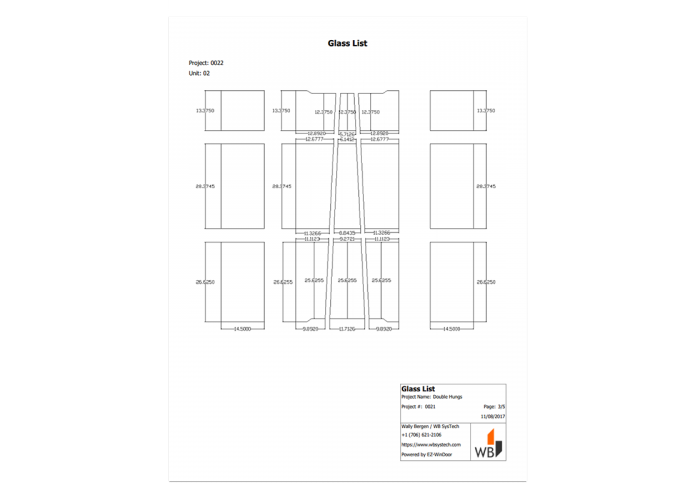

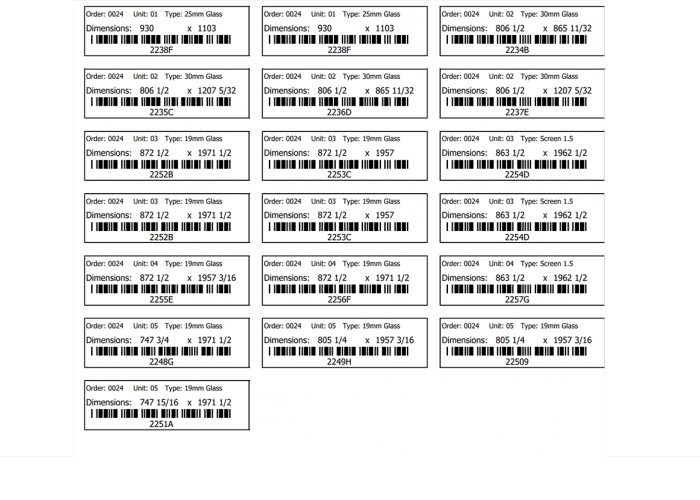

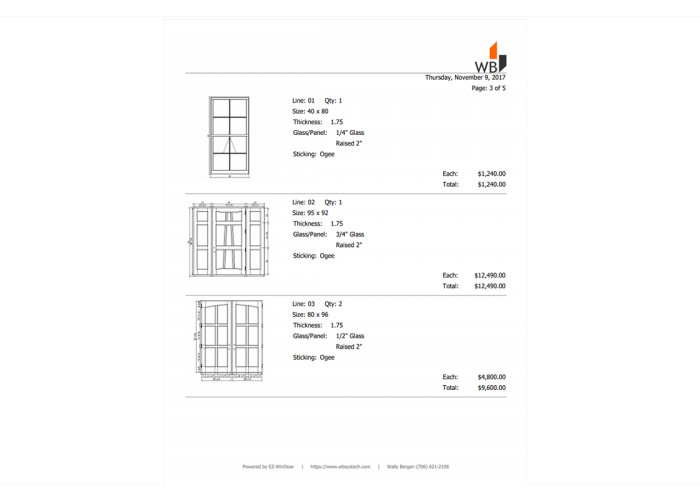

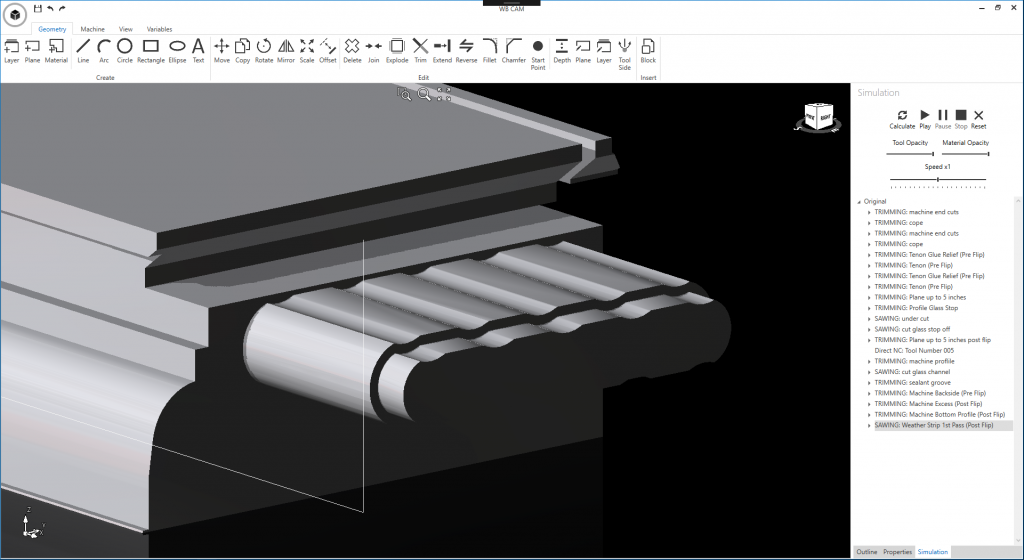

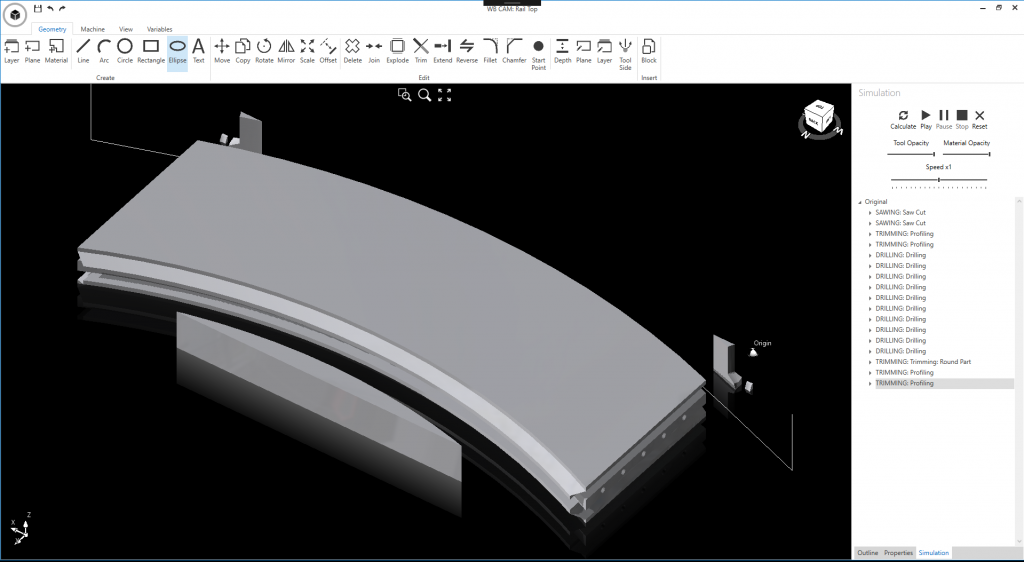

WB is the leading Software Solution for the Window and Door industry. From estimating with no limits in design and style, generating Bills-of-Material, Parts and Cut lists all the way to Paperless Production using Barcodes; WB simplifies the process, and can connect to CNC and Non-CNC Machines.

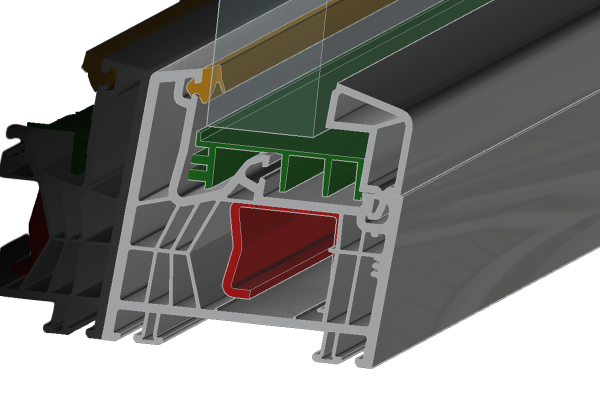

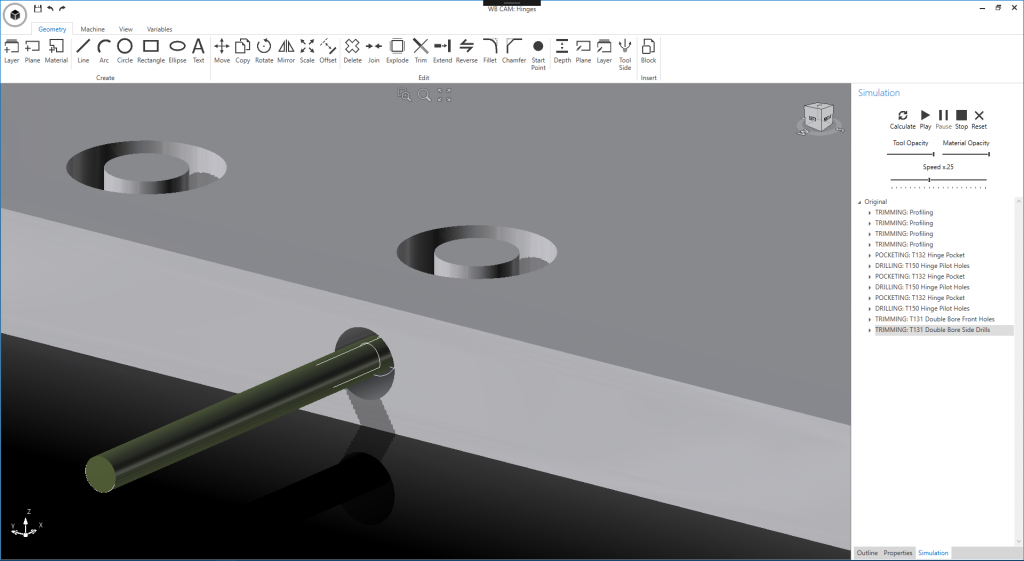

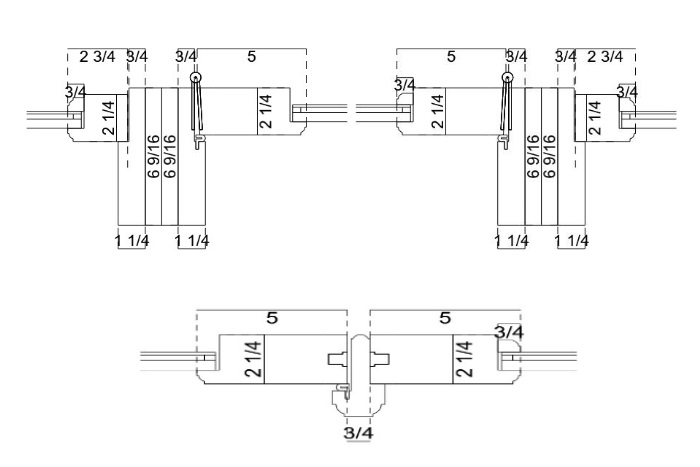

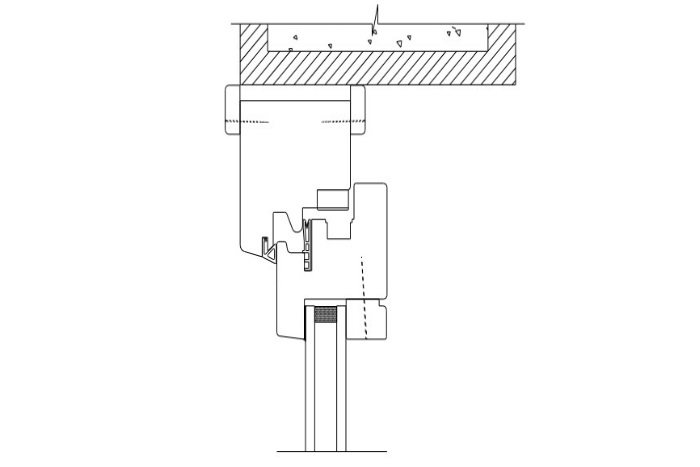

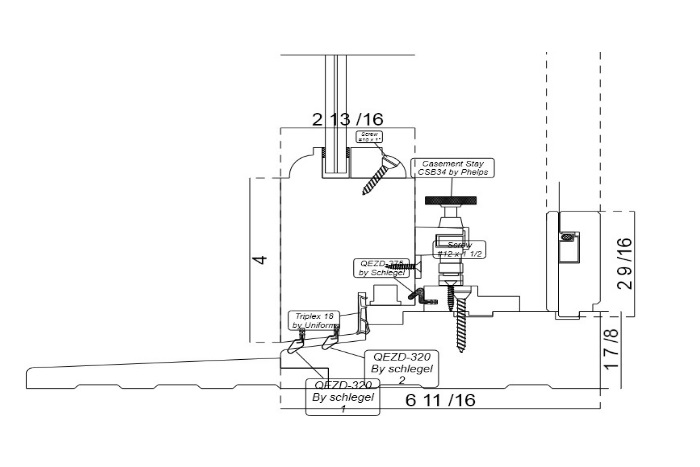

Hardware

Size depending Hardware resolutions. Using outside dimensions, certain rebate grooves or other references to determine the exact location of the hardware. Changing the unit size, automatically controlling and moving each hardware component to its location. Making sure that each piece of hardware will fit after the unit is assembled and pre-hung. Hardware can be set up for American Style as well as European Style of Windows and Doors (Casement, Awning, Hoppers, Hung-System, Sliding-System, Folding-Doors, Exterior and Interior Doors, Tilt’nTurn, etc.).

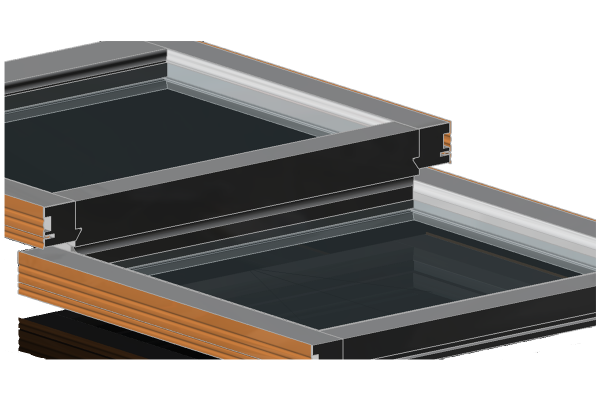

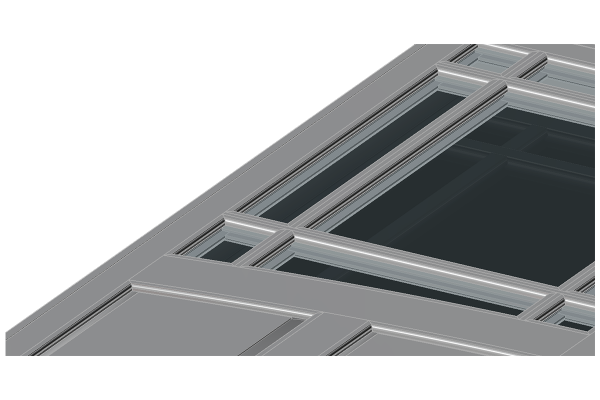

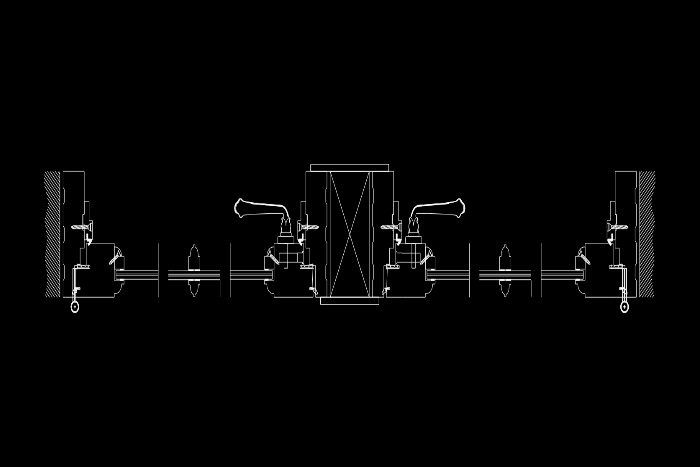

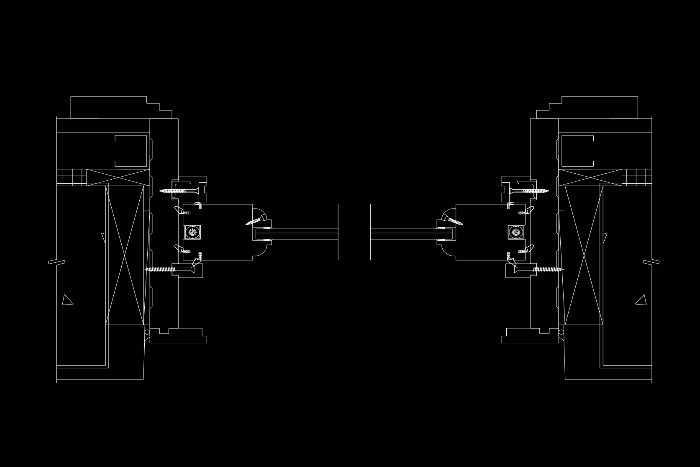

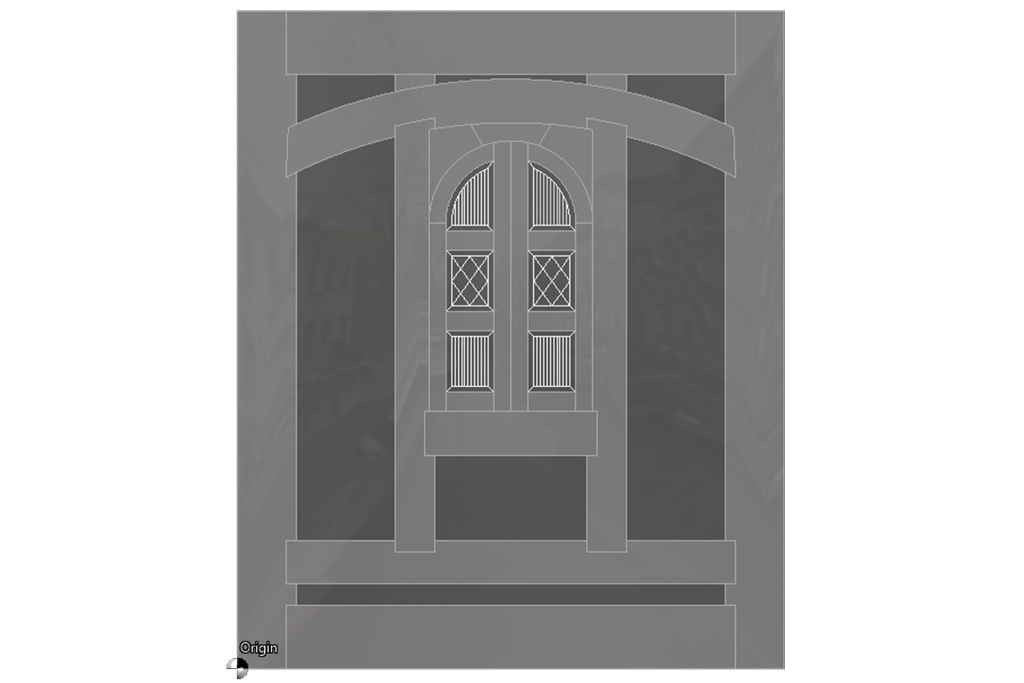

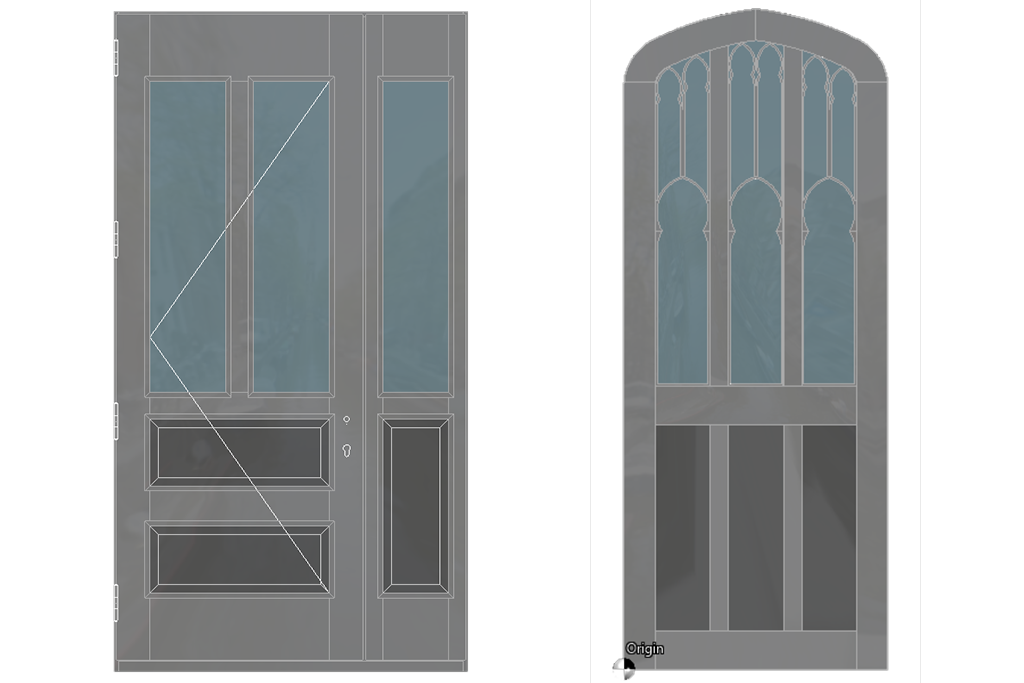

DXF

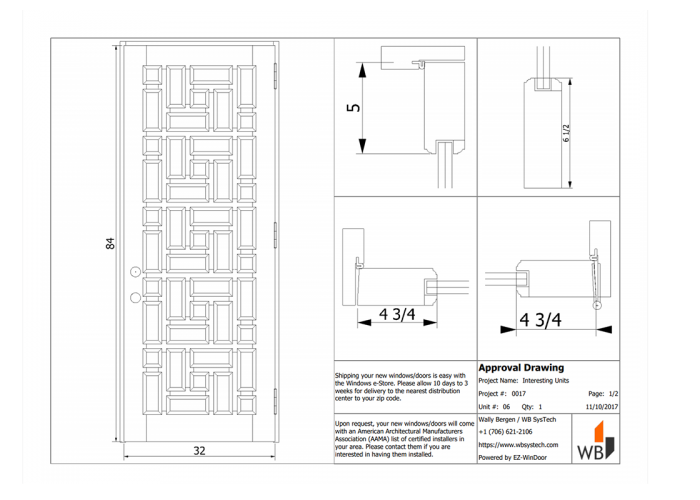

Generate parametric Cross-Sections and Elevation Drawings automatically. Present Interior and Exterior Views including the Opening Scheme based on the Hardware Selection. Changing a parameter (eg. Stile Width) will automatically adjust the Section and Elevation drawings.

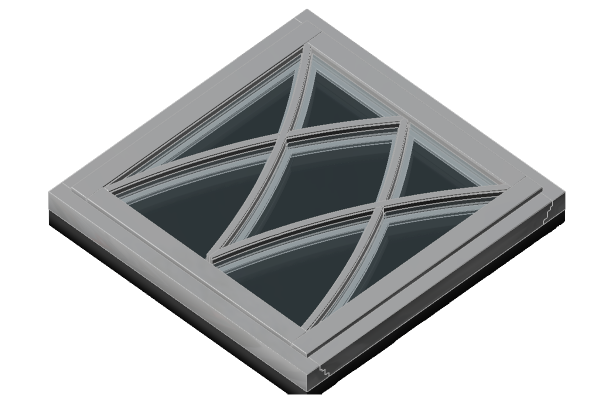

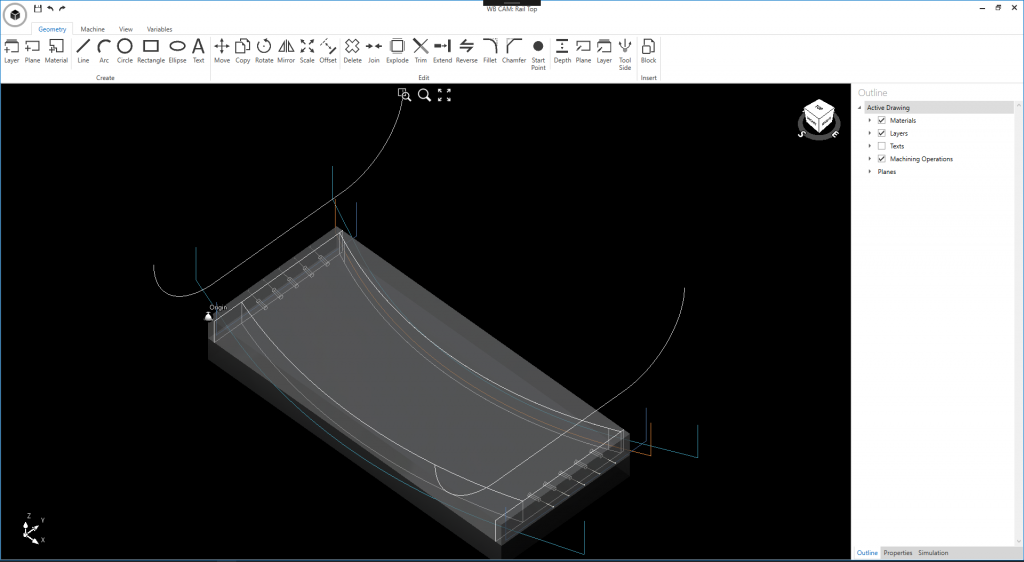

Custom Design

From rectangular design to angular or radius units. If you can think it, you can make it. Combine slant and curved parts in one unit. Anything designed can also be manufactured and machined. Reports with radius and angle information will be generated, and CNC machine code will be calculated automatically.